1

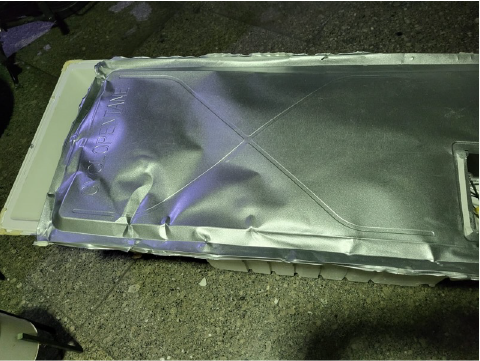

Tear down

the complete physical product to the last screw

Time taken – 4 to 5 days

The project was done for BSH (Bosch Siemens Home Appliances) wherein it was desired by us to reduce the cost of their Refrigerator model manufactured in their own facility in Chennai.

The idea was to make the refrigerator cost competitive to scale up the selling volumes. The Company wanted us to look at the overall product cost from an outsider’s perspective and create alternate sourcing solutions.

At the same time, BSH plans to replicate and extend similar activity to their other models and segments.

EDL was advised to relook at the complete product BOM and costing to arrive at a considerable cost reduction without compromising on the product’s performance and quality.

Minor tweaking in specifications as per the industry standards & getting more competitive vendors on-board.

Compare product specifications with couple of other leading refrigerator brands.

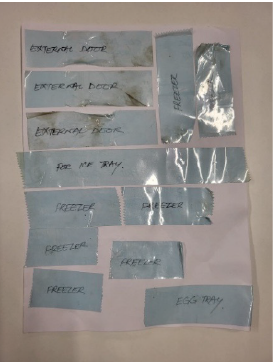

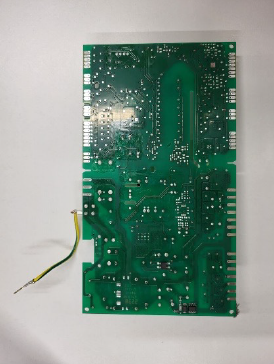

EDL was expected to tear down the complete actual refrigerator to the last screw and prepare the Bill of material and product costing without any inputs from BSH team. During this phase, BSH did not share the basic specs and part drawings and the idea was to arrive at a product cost from an outsider’s perspective.

EDL unassembled the complete product and prepared a detailed BOM + cost and the results of the exercise were very promising wherein a considerable reduction could be seen in cost of the refrigerator

To identify new vendors for the bought-out part and conduct commercially negotiate with them on behalf of BSH appliances. During this phase, BSH provided all the component specification and drawings along with 3d models wherever necessary. The whole project is controlled with a very stringent NDA.

Apart from identifying a new and an alternate vendor base, we also compared the part specifications with competitor products which gave some essential and value-added insights beneficial for future developments.

1

Re-initiate dialogue and negotiate with vendors shortlisted in Phase 1

2

Part level benchmarking with at least two brands

3

Propose changes in specs wherever possible without compromising on quality and performance

4

Submit final Bill of material with proposed specs and vendor changes