Case study –

Air Fryer (Make in India)

Background

The Government of India’s initiative of “Make In India” has given a huge and a big boost to the Indian manufacturing industry. The incentives offered by the government are lucrative and the overall sentiments are very positive.

At the same time with agencies like BIS becoming more aggressive and stringent there is a big impact on imports and the concept of “Make In India” is gaining momentum

Problem Statement

There are many products across home appliances & consumer durable segments which are currently being imported. The imports are an expensive option with higher lead times and they do not give the flexibility of designing and customizing products as per the choice

Challenges

There is not enough eco-system available in terms of design, development, tool making and manufacturing of high end appliances & other products. The availability of internal functional parts too is a challenge and also limited resources are available for electronic printed circuit boards.

Project

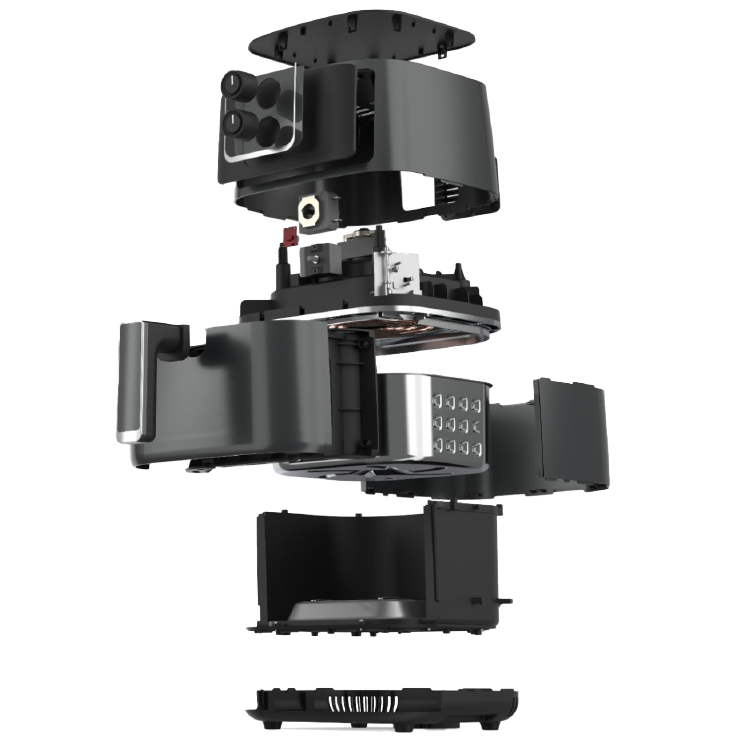

Epack durables limited, the leading OEM / ODM for Home appliances and White goods approached us for design, engineering and development of India’s first indigenized Air fryer.

Solution

Our diverse team with an extensive hands-on experience and an in-depth understanding of the manufacturing eco-system have delivered hundreds of product development projects in the past.

In addition to the Air fryer, we have earlier delivered a completely indigenized OTG (Oven toaster griller) in the 32 ltr capacity and currently working on a Pop up toaster as our third project under the “Make In India” initiative

Services provided –

- Competitor benchmarking

- Ideation and industrial design

- Product engineering

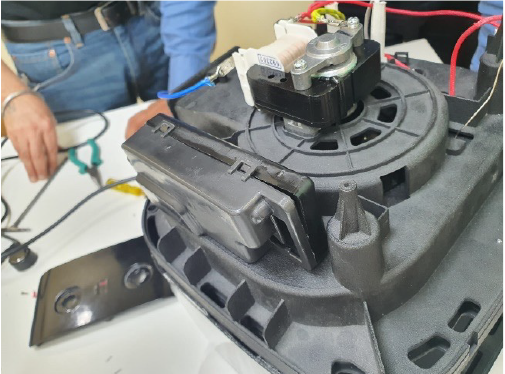

- Functional prototyping

- Soft tools for sheet metal drawn cooking bowls

- Bill of material and product costing

- Vendor identification in China for imported components

- Part level technical specifications

Key value additions –

- Enhanced air flow through a breakthrough design of the cooking bowl – patent applied.

- Engineered two bowl sizes within the same product housing for optimized tooling investment.

- Mechanical and digital variants.